What Is a Box Packing Machine and How Does It Work in Secondary Packaging?

The secondary packaging process is where products become pallet-ready, shelf-ready, and ready for distribution, and box packing machines (also called case packers) are the workhorses that make that happen reliably at scale.

The latest estimates of the packaging automation sector exceed approximately USD 78.26 billion in total value, with an anticipated continued growth rate of about 8.20% based on the demand for secondary packaging from the e-commerce, food, and FMCG sectors. The market for secondary packing alone represents a multi-hundred-billion-dollar market.

What a Box Packing Machine Actually Does?

A box packing machine automates the process of forming, loading, and sealing cartons or cases around products that have already been through primary packaging. At the end of the line, it is a box packing machine that takes bottles, pouches, sachets, or prepacked multipacks and places them precisely into a box, then seals that box for palletising or shipping.

Why does this matter?

- It removes variability from manual packing, improving fill accuracy and pack integrity.

- It increases throughput and reduces labor costs per case.

- It standardises box presentation for downstream automation (stretch wrap, palletising, truck loading).

Core Components and How They Work

Let’s break it down into the core stages most automatic box packing machines follow.

1. Case Supply and Erection

Cartons are stored in a powered magazine. The carton will be formed by the machine from a flat blank through the use of a driven erector mechanism (powered magazine + automatic case erector).

2. Product Orientation and Grouping

Upstream conveyors and infeed guides orient products into the right formation (singles, multipacks, trays). Some lines use robotic or gantry pick-and-place systems to build patterns for fragile or irregular items.

3. Loading/Insertion

For loading and inserting the products into the cases, robotic pick-and-place systems, gantry systems, drop-in styles, and pushers are used. The method of loading will depend on the type of fragility of the product, the configuration of the product pack, and throughput requirements.

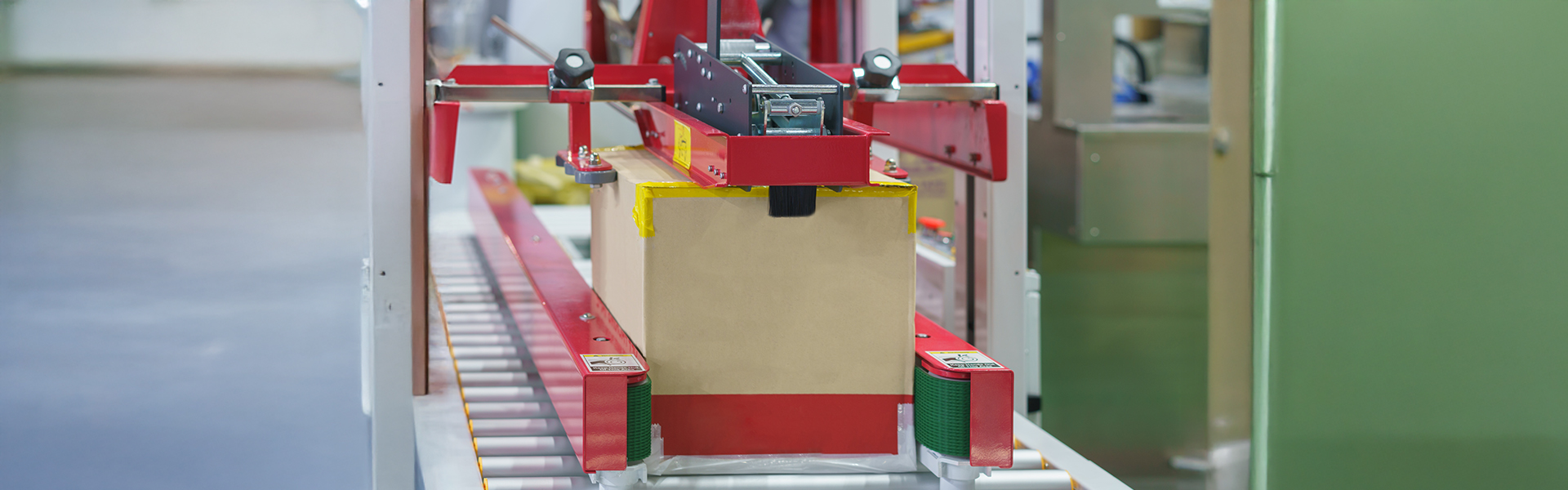

4. Case Closing and Sealing

After loading, the machine will be able to seal the top flaps of the box by closing and adhering the top flaps with glue, tape, or tuck-style sealing methods. Additionally, current systems allow for consistency in the amount of pressure used with seals and provide for an inspection of the case before being pushed downstream for the bulk of the product handling system.

5. Outfeed and Accumulation

Finished cases are discharged to conveyors, accumulation tables, or directly to palletising stations. Integration with stretch wrappers and robotic palletisers forms a complete secondary line.

Types of Box Packing Machines

- Top-load case packers: products are loaded from above; excellent for stable, high-speed lines.

- In-line/straight packers: product is pushed directly into a case on the same line.

- Robotic/gantry pick-and-place packers: best for flexible layouts, fragile products, or mixed SKUs.

- Wraparound case packers: create a sleeve around the product, making them highly efficient for fixed formats.

A Real Example of Performance and Specs

To illustrate this, Alligator Automations’ case-packing solutions list typical machine speeds at 10–20 cartons per minute for certain erecting/packing units, with support for regular slotted cartons (3/5 ply), powered carton magazines, pneumatic/servo drives, and multiple sealing options (tape, glue).

Pack types supported include pouches, bottles, cups, bars, and trays; packer mechanisms offered range from robotic pick-and-place to gantry and pusher types.

Machine footprints vary; for example, compact models show dimensions and weights in their spec sheets. These are practical choices for FMCG and light industrial lines where throughput, reliability, and integration matter.

Business Benefits — What Operations Care About

- Throughput and consistency: Automated case packers reduce variation and support predictable downstream cycle times.

- Lower cost per case: Automation decreases the number of manual operators used (6-12) per line in medium speed applications, reducing the labour cost significantly.

- Scalability and flexibility: Modular machinery and robotic packaging systems allow for faster SKU addition with no complete line rebuild.

- Reduced product damage and better load stability: Packing products in a consistent manner drastically increases the stability of the pallet and reduces the risks associated with transit damage.

- Faster ROI: Though it will require a significant capital investment, the ROI for automation comes from labour savings, decreased reject rates, and increased throughput – all of which make the justification to automate most modern secondary lines.

Best Applications for Box Packing Machines

Secondary box packaging machines have extensive applications in a variety of industries, including fast-moving consumer goods (FMCG), food and beverage, pharmaceuticals (only for secondary production), cosmetics, and consumer products. This is true for any product that is grouped to form a case, requires a strong seal, and needs to be palletised for distribution. Box packing machines are critical when the end-user demands that their product be packed in a consistent, timely, and repeatable manner.

Alligator Automations’ box packing solutions are engineered with modular packer types (robotic, gantry, pusher), powered magazines, and servo-driven motions to balance speed, accuracy, and minimal changeover — making them a fit for plant managers aiming for reliable secondary automation.

Conclusion

A box packing machine is the backbone of any efficient secondary packaging line: it converts primary-packed product into consistent, transport-ready cases while cutting labor and error. If you’re evaluating automation, pick a solution that’s proven for your SKU mix and integrates seamlessly into the downstream pallet-handling chain.

Alligator Automations supplies the box packing or case packing machine and complements it with a full secondary line: bag filling machines, intralogistic conveyors, case packers, depalletizers, robotic palletizers, stretch wrappers, and automatic truck loading solutions a complete packing and bagging line backed by lifetime after-installation support.

Want a line layout and throughput estimate for your SKU mix? Reach out to Alligator Automations today.

FAQs

- What is a box packing machine used for?

It forms, fills, and seals cartons around primary-packed products to make them ready for palletising and shipment. - How does a box packing machine work in secondary packaging?

It erects a carton, orients and inserts products using mechanical or robotic systems, then closes and seals the case before handing it to downstream conveyors or palletisers. - What types of box packing machines are available?

Top-load, in-line/pusher, robotic/gantry pick-and-place, and wraparound case packers are common types, chosen based on product and throughput needs. - Is an automatic box packing machine suitable for all industries?

Most industries with packaged goods benefit, but suitability depends on SKU variability, required throughput, and product fragility. - What products can be packed using a box packing machine?

Pouches, bottles, trays, bars, cups, cartons, and many other primary-packed goods — essentially anything that can be grouped and inserted into a case.